3D printed jewellery

With the invention of the 3D printer is was inevitable that designers would start making 3D printed jewellery. LJS tutor Anna Campbell investigates the current state of 3D printing and jewellery.

3D printing is the process of making a 3D object from a digital file. The objects are typically ‘printed’ in layers from a plastic filament or resin. To see how 3D printing works have a look at this youtube video.

Although 3D printers are still relatively expensive it is suggested that at some time in the not too distant future we’ll all have one in our homes.

I was able to understand more about this when I visited an exhibition on 3D printing at the Science Museum (which is now on show at the Museum of Science and Industry in Manchester). The exhibition showed examples of objects that can be printed now and possibilities for the future. I was struck by the possibility that, if our washing machine broke down, we could print a new part.

So, how could this relate to jewellery?

Printing in plastic or resin

Jewellers may use this medium to make finished pieces of jewellery. However it can also be used for making prototypes and models for casting and moulding.

Printing in wax

A design printed in wax can be cast in metal using the lost wax casting process (see a blog post I wrote about the process of lost wax casting here).

Printing in metal clay

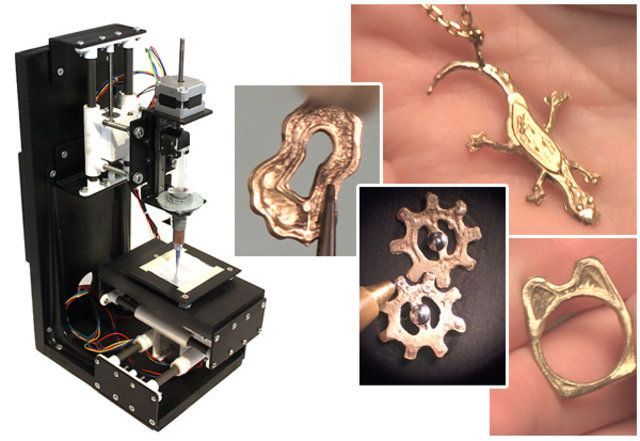

Printed metal clay jewellery

Given the way 3D printers work it was inevitable that metal clay (syringe clay) would become a medium used.

A company called Mini Metal Maker have created a metal clay printer that currently prints in bronze clay (but would be able to print in any metal clay). They have been using a crowd funding company called Indiegogo to raise more money to commercially manufacture the printers and make them more widely available. They recently had success printing some bronze scissors. As with any metal clay the piece still needs to be sanded and kiln fired so the use of these printers is likely to be of a smaller scale than plastics.

How do I design for 3D printing?

As with ordinary printing, a 3D printer needs to be connected to a computer so you would need to learn how to create your designs using a Computer Aided Design (CAD) program.

Where can I see 3D printing in action?

iMakr, the largest independent 3D printers in the world, just happens to be right next to Hatton Garden in London. You can pop in to see a 3D printer in action, get a design of your own printed or enquire about buying a 3D printed for use at home. You can even get a mini you made.

The value of handmade

Does the ability to print jewellery devalue handcrafted jewellery? I don’t think so. We already have mass manufacturing of jewellery available and people still value the handmade and handcrafted approach to jewellery. I hope that 3D printing becomes an addition to our armoury rather than something that takes away from our industry. Imagine being able to print your own chain and clasps.

Anna Campbell is a tutor at the London Jewellery School and runs her own jewellery business Campbell Hall Designs. She sells online from her website and at the Things British shop in Greenwich, London.